LTEOIL’s non-equilibrium processes transform our planet’s endowment of hydrocarbons into the carbon with which to build society and the hydrogen to power it, net zero emissions. The process begins with ubiquitous natural gas, a plentiful and inexpensive feedstock, and produces both valuable solid carbon and inexpensive hydrogen in ambient conditions at scale. The LTEOIL plasma process requires much lower energy input than competing processes for carbon production (such as methane pyrolysis) and hydrogen production (such as water electrolysis). LTEOIL carbon and hydrogen production could take place near the point of use (anywhere on the natural gas network) or anywhere that natural gas is currently flared, transforming a waste stream into a valuable product and enabling massive emissions reductions.

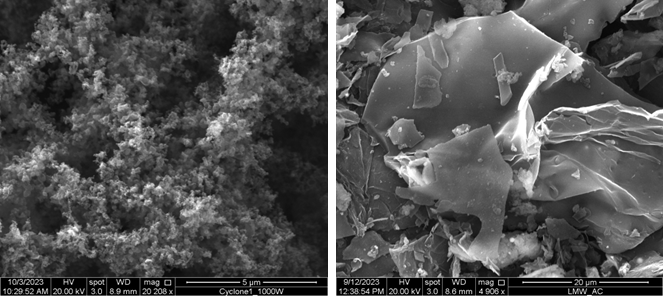

Engineered Carbon Nanomaterials

The LTEOIL process produces valuable carbon products in significant demand for both current applications (e.g. lithium ion and lead acid batteries) and emerging applications (solid state batteries, carbon semiconductors). Depending on input parameters, LTEOIL reactors can produce either carbon nanosheets or carbon nanoparticles, both of which are sought-after products in markets with significant growth expected in the coming decades.

A New Color of Hydrogen

Hydrogen is expected to play a major role in the energy transition, but both green hydrogen (from water electrolysis) and blue hydrogen (from steam methane reforming with carbon capture) have significant drawbacks in terms of capital and energy cost. LTEOIL offers a unique direct process for production of both of these components of energy transition, capitalizing on the advantages and mitigating the disadvantages of competing processes.